Freeform Future Corp., a startup using custom 3D printers to make metal parts, has raised $67 million in funding.

The corporate stated in its announcement of the deal today that Nvidia Corp.’s NVentures and Boeing Co.’s AE Ventures were among the many participants. They previously backed Freeform’s Series A raise in 2024. The corporate’s latest round also included contributions from Apandion, Founders Fund, Linse Capital, Threshold Ventures and Two Sigma Ventures.

Metal components are typically made using large, automated cutting tools called CNC machines. Such machines will be difficult and time-consuming to establish. That makes them impractical for certain low-volume manufacturing tasks. Spending months to establish a CNC production line that can make only a handful of parts often isn’t economic.

In lots of cases, metal 3D printers of the type utilized by Freeform offer a more cost-efficient alternative. Engineers can program a 3D printer to make a certain part after which reconfigure it to provide one other relatively quickly. Consequently, the prices related to organising a production line are lower than with CNC machines. Moreover, 3D printers often produce less metal waste.

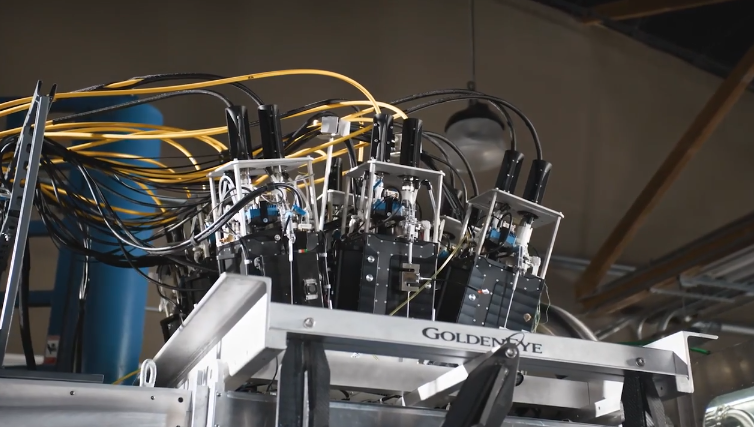

Freeform has developed a 3D printing system called GoldenEye that’s specifically optimized for metalworking. In line with the corporate, it uses 18 lasers to make parts from metal powder. Built-in sensors collect data in regards to the manufacturing workflow to discover areas for improvement.

Essentially the most common 3D printing approach that involves lasers and metal powder known as SLM. An SLM printer deposits a skinny layer of metal particles on a flat substrate and melts them together into shapes using laser light. It then deposits one other layer of powder, melts it and repeats the method until the component is prepared.

SLM printers’ lasers are typically powered by a highly modified fiber-optic cable. The cable often comprises multiple layers and includes ytterbium, a rare-earth element that can be used to make quantum computer qubits.

In line with TechCrunch, Freeform’s 3D printing hardware is supported by on-premises server clusters equipped with H200 graphics cards. The chips run simulations that help the corporate improve manufacturing quantity and quality.

Quality optimization is a very important element of the 3D metal printing workflow because 3D printers are vulnerable to certain errors. If a printer doesn’t spend enough time heating metal powder, the powder may not fuse properly, which weakens the structure of the component being fabricated. That may result in cracks and other defects.

Freeform doesn’t sell 3D printers, but as a substitute operates a 3D printing facility where it produces parts for patrons. The corporate says that its approach removes the necessity for organizations to construct production lines and hire technical staff, which lowers costs.

Freeform will reportedly use its funding round to upgrade its GoldenEye 3D printing system. The corporate is working on a new edition that features several hundred lasers and can be capable of creating “hundreds of kilograms of metal parts” per day.

Freeform plans to disclose the system, which it calls Skyfall, within the second half of the 12 months. The corporate expects the machine to spice up its manufacturing capability by an element of greater than 25. Freeform will hire as much as 100 recent employees to support its growth efforts.

Photo: Freeform

Support our mission to maintain content open and free by engaging with theCUBE community. Join theCUBE’s Alumni Trust Network, where technology leaders connect, share intelligence and create opportunities.

- 15M+ viewers of theCUBE videos, powering conversations across AI, cloud, cybersecurity and more

- 11.4k+ theCUBE alumni — Connect with greater than 11,400 tech and business leaders shaping the long run through a singular trusted-based network.

About SiliconANGLE Media

Founded by tech visionaries John Furrier and Dave Vellante, SiliconANGLE Media has built a dynamic ecosystem of industry-leading digital media brands that reach 15+ million elite tech professionals. Our recent proprietary theCUBE AI Video Cloud is breaking ground in audience interaction, leveraging theCUBEai.com neural network to assist technology firms make data-driven decisions and stay on the forefront of industry conversations.